The glare from these sheets brings complaints from F-16 fighter pilots based nearby, but that’s a problem for another day. “You don’t want to upset someone who carries a missile,” Carlos de Jesus, Amorim’s head of marketing and communications, jokes as he shows me around one of the company’s four stopper production plants. We are following the trail of cork from a forest in Coruche, in southern Portugal, to finished product.

The scale of the operation is impressive. The planks in front of me are stacked 2.5m high and spread over the equivalent of 11 football pitches. They will dry here for six to nine months before the production process begins. Only about 30% of the cork in front of me will make it into bottles. The rest will end up in shoes, floor tiles, furniture, yoga mats, soundproofing materials, and accessories such as handbags, purses, wallets, mousemats, and iPad covers. Some may even end up in space, as cork is used in the thermal protection for a rocket’s external fuel tank.

Every bit of the plank is used for something. The dust created from trimming the bark, sawing it into sections, punching out corks, and grinding the rest into granules is swept up and burnt to generate energy for the factories.

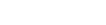

Carlos (above), who has been with Amorim for 15 years, is clearly in love with the product and its incredible cell structure. Every square centimetre comprises approximately 40 million cells, which give it a unique set of qualities:

- It is very light, yet impermeable to liquids and gases;

- It is elastic and compressible;

- It is natural, renewable, and recyclable.

Its one downfall is TCA (2,4,6-trichloroanisole), a natural compound that at higher levels can impart ‘musty’ flavours and aromas to wines. It can come from a variety of sources, including barrels, drains, shipping containers, and wooden pallets, but the main culprit is cork.

Amorim says it has already got the problem licked with its technical corks, like Neutrocork, because each granule can be steam-cleaned before the cork is agglomerated.

Champagne and sparkling wine stoppers – agglomerate corks topped and tailed with natural cork disks – will be guaranteed TCA-free (that is, have concentrations of releasable TCA well below any sensory threshold) by October. The technology already exists but scaling it up to industrial numbers – where Amorim can carry out the final gas chromatography examination in seconds – is another matter. Those machines, called NDTech Sparkling, are now being installed in Amorim’s plant near Porto.

NDtech Sparkling uses the same technology as the original NDtech process, launched three years ago for natural cork stoppers. This has now been upgraded to NDtech 2.0 – machines that are less expensive to maintain but still detect TCA above 0.5ng/L (TCA’s sensory threshold is around 1 to 5ng/L).

The aim is to produce more than 4 billion corks a year with each cork individually analysed before despatch, so Amorim can guarantee there are no non-detectable traces of TCA in any of its corks.

'This week we have declared the total eradication of TCA on Champagne stoppers'

Antonio Amorim (above), chairman and CEO, told Canopy: “We have clearly stated by the end of 2020 that every single cork that leaves our premises must be individually guaranteed… This week we have declared the total eradication of TCA on Champagne stoppers. We have prototype NDTech Sparkling machines being installed from August onwards.”

The battle begins

Inside the factory in Ribatejo, I see for myself where the fight against TCA begins. Before each critical point for the formation of TCA had been identified, the planks were left on the ground in the forest until they were needed. Now they are removed immediately, stored on metal pallets, and stacked to ensure good aeration. Other preventative measures include:- Boiling for an hour, without pressing down, to kill all insects and bacteria and to make the bark more flexible;

- Using their own water in case the municipal supply contains chlorine (a major contributor to the production of TCA);

- Sawing off the bottom section of the plank – the part that has been in contact with soil microorganisms;

- Manually checking each plank for signs of fungus or bacteria while grading them;

- Punching the corks (either manually – below – or by machine) within three days of coming from the sterilising machine;

- Using steam chambers – ROSA for granules, ROSA Evolution for natural corks, and SUPER ROSA for natural corks and disks – to sterilise the cork;

- Optically sorting the corks for quality;

- Analysing 45,000 samples a month with SPME gas chronometers.

“Alone, these measure are not going to cut it, but combined they are very effective,” Carlos says.

However, although TCA is being eliminated from corks, it is more prevalent in the environment. “Because TCA does not migrate through cork, it’s a very good protection against environmental contamination,” Carlos points out. “And that is the ultimate irony and a good measure of how things have changed.”

New opportunities

With the battle against TCA nearly won, Amorim is researching cork stoppers’ role in improving top wines.Antonio Amorim tells Canopy: “We have done our utmost to improve the technical performance of cork, to bring cork from a negative perception to zero, but we want to go beyond that. We believe that cork cannot only be a neutral closure but can also add value to wine – improve the sensory performance of a wine.”

When the ‘tiradores’ cut the bark from the Quercus suber tree, the cork smells of oak. Although the aroma disappears with the various sanitising treatments, compounds found in oak barrels – such as suberin, lignin and polysaccharides – migrate from the cork to the wine in tiny fractions over time.

Amorim’s research and development director, Dr Miguel Cabral (above), says the extraction of dozens of phenolic, volatile and semi-volatile compounds from a cork is 5mg/L equivalent Gahlic acid after one year and 15mg/L after three years (from a barrel it’s more like 150mg/L).

Miguel explains: “It’s very difficult to extract things from cork – because cork has a network of cells and these cells are closed one to the other in a polyhedral way. You need to have a very strong process to reach the cells that are inside the cork. It’s not easy. It’s the same thing as for oxygen. In theory, when we squeeze the cork to put it in the bottle we could have a whoosh of oxygen coming out but we do not have that; we have oxygen slowly coming out – because the oxygen that is in the interior of the cells has to pass millions of layers of cork cells to reach the outside, and that takes time.”

With only a small area of cork in contact with the wine, Miguel says the influence is “below any sensory threshold. However, slowly, the compounds are extracted from the cork to the wine and react with the wine matrix because, as we all know, a bottle of wine is a chemical reaction.”

He adds: “The compounds released by the cork react with those present in the wine, favouring the formation of more complex compounds that increase the stabilisation of the colour of the wine, contribute to the formation of the bouquet, reduce astringency over time and have antioxidant and anti-cancer properties.

“This is why a long cork is important for long ageing of wines.”

.png)