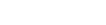

Joško, who helped make qvevri wines and skin-contact whites trendy, plans to create an ‘amphora garden’ – with the new arrivals buried in the ground outside his winery in Oslavia, a small village in Friuli’s Collio region.

He wants to see if there is a difference between fermenting the musts inside or outside – or, as he describes it, “with the universe”.

“When he has a curiosity, he needs to find an answer,” his daughter, Mateja, tells me. “Will the fermentation be slower or faster? All these things are interesting for us to see.”

The qvevris should have arrived in May or June – in time for the Gravners’ 2020 vintage – but they arrived during the harvest, when there was no time to inter them (an operation that would take three or four days).

Joško bought some qvevri for his garden experiment last year, too, but he ended up using them to replace some of the original qvevris he buried under his winery in 2001 (above), when he completely turned his back on the modern winemaking methods that had brought him success during the 1980s and 1990s. Although qvevris can last hundreds of years, they can get chipped during punchdowns and some, the Gravners discovered, were cracked, possibly from the 2016 earthquake in central Italy. There are 47 of them buried in the soil under the winery, which is supported on 18-metre tall steel piles (above).

When I ask Mateja why her father plans to bury a dozen, she replies: “Joško is not able to make a little test.”

As there are differences in the sizes, shapes and thicknesses of the manmade qvevri, 12 “gives a better idea of what’s going to happen” and gives them the chance to blend and “rebalance” the resulting wines.

“This does not mean we will move the whole production from inside to outside, the idea is to see what would happen,” Mateja stresses.

She also denies it is another risky development for the pioneering winemaker. “We are not gambling, it’s just to see,” she says, pointing out it will be relatively easy to move the wine inside if things get too funky.

With the delay in the arrival, it gives them time to prepare the holes properly and also to work out some of the details – like how to do punchdowns in the rain. Joško's three assistants want to erect a canopy but he says it will change the temperature of the air above the qvevris.

“There are a lot of small things we have to consider with attention and care because everything has some positive and some negative effects,” Mateja (above) says. “But what I’ve learned working with Joško is that… at the end there is a solution for everything.

'If you plan everything, it will never be as you plan'“If you plan everything, it will never be as you plan, so it’s probably better just taking things as they come and try to accept them and to work with what you have.”

One thing is certain – it will be Ribolla Gialla going into the qvevris. That’s Gravner’s main grape variety and accounts for about 85% of the family’s annual output of 35,000 bottles. This signature ‘orange/natural’ wine is a blend of Ribolla from different parcels and different amphorae.

One problem with having 13 of 18ha planted with one variety is that it all ripens at about the same time. It takes them 15-17 consecutive days to hand-harvest the “very ripe” grapes into 20kg crates – using experienced pickers to clean the bunches of rotten berries as they go along, as the bunches go straight into the qvevris. Joško has been doing whole-cluster fermentations since 2017, following some successful experiments in 2016. It has enabled them to reduce the time on skins as the stems keep the skins submerged during fermentation.

The rest of the winemaking has been consistent since 2001:

- The first grapes in the qvevri get a little SO2;

- Fermentation with native yeasts;

- Long macerations;

- No temperature control.

After MLF, racking and pressing (in a hydraulic basket press that’s large enough to take skins from two qvevris), the wine is poured back into the terracotta containers for at least five more months before it is blended and aged for five or six years in large Slavonian oak barrels (1,000-1,300L).

The wine is racked to a large stainless-steel tank prior to bottling to check the level of sulphites. The target is 15-20mg/L free, 40-90mg/L total – most of which is added during the racking to barrels.

The wine is then bottled “on a waning moon” without fining or filtration.

It’s all very simple – and in keeping with their philosophy. Wine is a food substance, so it should be made simply “because it is going into our bodies and our bodies haven’t changed that much over the past 6,000 years.

“The simpler it’s done, the simpler it is for our bodies to accept, digest and use.”

They were bottling the 2013 vintage and moving the 2019 to barrels during my Zoom call with Mateja.

I asked about the cleaning regime as this is often cited as the downside of qvevri. She says a cellarhand climbs in and washes them with cold water and, prior to harvest, with soda and warm water.

Like most Georgian qvevri, they are lined with beeswax. Some of their original 20-year-old qvevris were relined last year, heating them slowly to 95°C to remove the old beeswax and re-coat them with ‘organic’ beeswax from neighbouring Slovenia (where they have two of their three vineyards). They managed to reline three a day and, Mateja says, it took “a lot of power”.

Few people, she says, can pick out wine from new or old amphorae.

The winemaking is very similar for their red wines, except they spend less time on skins and the amount of time in clay and large oak is “more flexible”.

Their main red is also made from one of Friuli’s indigenous grape varieties, Pignolo. Their other red, Rosso Gravner, comes from what’s left of the international varieties that made Joško famous in the first place but have since been replanted – a couple of small parcels of Merlot and Cabernet Sauvignon planted in the 1960s.

More special releases

For a world-renowned winery, the range is very limited. What we may see in the coming years, according to Mateja, is more special releases, such as 8.9.10 (a blend of late-harvested, botrytised Ribolla from three vintages), and special selections, such as the Reserva 2003 Ribolla from their oldest vineyard. Currently, the different parcels are harvested and vinified separately, but then blended. “So, the idea for the future is to get a little bit more connected to the single parcel,” Mateja says.

Mateja also mentions a couple of recent changes in the beautiful vineyards, which look more like gardens (above):

- They no longer trim the shoot tips – they roll them round the top wire instead. It’s a very labour-intensive practice but Joško believes it’s less stressful for the vines. They have restarted trimming the side of the canopy, though, to aid spraying.

- They grow the American rootstock in the vineyard for one or two years before grafting on the Ribolla or Pignola scions.

Her 26-year-old son, Gregor, has just completed his third harvest by his grandfather’s side. He didn’t see the original qvevris being buried in Oslavia, but he will help to inter the new ones.

.png)