The design of the front of the machine was inspired by the shape of a Champagne flute – tall, wide at the top and tapering down at the bottom. This shape, together with wraparound glass, provides the operator with exceptional visibility of the vines and all around. The rest of the exterior design stands out for the flowing and dynamic automotive-inspired lines, with the exposed frame conferring a sporty look. The shape of the cab, angled in the direction of travel, adds to the vehicle’s dynamism.

The interior, accessible via the large single door and rotating seat, offers a supremely comfortable environment for the driver. The use of wood trim contributes to the cab’s plush, luxurious feel, and was inspired by wine barrels.

The concept was developed with car design mavericks Pininfarina.

Carlo Lambro, New Holland brand president, said: “Our ground-breaking Straddle Tractor Concept offers a glimpse into the future that premium winegrowers with narrow, high-value vineyards can aspire to.”

Features include the ability to multiply its width – to straddle multiple rows – at the push of a button, an electric powertrain and airless tyres.

Another prototype from New Holland is this electric weed control machine, unveiled at last month’s Sitevi exhibition in Montpellier, France. The tractor manufacturer, through its technology subsidiary AgXtend, says the Xpower XPN electric weeding tool is for narrow vineyards. Mounted on a Braud 9070 N high-clearance tractor, the 4-module prototype for one row and two half-rows is hydraulically driven, instead of the PTO for the already familiar model on inter-row tractors.

The 36kW (50hp) generator sends 8,000 volts to the applicators. Mounted on a pivoting inter-vine appliance, they weed over a width of 40cm, all of which is controlled from the Intelliview 4 screen in the cab.

Development of the tool is still ongoing and is focusing on bringing the electrocution module closer to the ground. The aim is to adjust to the trellising and vineyard management techniques of narrow vines with low bunches of grapes, and thus avoid breakage. Also, unlike the prototype displayed at Sitevi, the moving electrode on a pivot will take on an elongated and rigid U shape instead of flexible strips. According to AgXtend, the aim is to have as few moving parts as possible, with the best possible ground tracking for the application modules.

The driving speed of the high-clearance tractor is the same as that of a conventional tractor: between 2 and 4km/h depending on soil and weather conditions and the density and diversity of the grass cover.

Another prototype unveiled at Sitevi is Traxx, a petrol-driven autonomous straddle tractor developed by Exxact Robotics. With one configuration designed for tillage and the other for spraying, Traxx is being tested at Château Montrose in Bordeaux. The tillage model is ready to go, but the spraying version, which uses parent company Tecnoma’s Panel’Jet recovery spraying technology, needs further field trials this growing season.

Traxx’s advantages, according to the company, include its small size (3.2m long), light weight (less than 1,500kg), a reduction of damage to branches (30% less breakage), and better adaptation to slippery and technically complicated grounds. But chiefly it’s the ability to go into the vineyard whatever the weather and soil conditions, and even when re-entry for workers is not possible. “Spraying the right dose, in the right place and at the right time appears to be a sustainable solution to meet the current and future challenges of viticulture that respects people and the environment,” says the company.

Although these products aren’t available yet, we have found seven magnificent new products that can be purchased and will be of interest to winemakers and viticulturists.

3D printing has come to the world of ceramic jars, eggs and amphorae, providing new possibilities for the manufacture of ceramic containers in terms of shape, reproducibility and technical performance that were previously unattainable with traditional processes.

It’s an interesting development, and it was one of only two new products at the 2021 Sitevi Innovation Awards in France to win a gold medal.

The Biopythos project, carried out in partnership with the company 3D Minerals, offers wine maturation vessels with precise levels of micro-oxygenation while remaining inert in relation to the wine. The stoneware vessels are made from ¼ clay, ¼ kaolin, ¼ feldspar and ¼ silica while the porcelain shapes are formulated from ½ kaolin, ¼ feldspar and ¼ silica, with kaolin providing whiteness.

Price of a 225L stoneware egg is €1,200, while the 550L version costs €2,650.

The Bucher XPlus press has drainage elements to recover the free-run juice as quickly as possible and reduce clogging as much as possible. These swivelling parts, which can be closed and opened without the need for tools, are also designed to increase the efficiency of the crushing action during tank rotation and to be easily lifted for cleaning.

R&D Vision’s Itria combines the use of highspeed 3D imaging, multispectral imaging (visible and infrared) and artificial intelligence/deep learning technologies to check the quality and sort crates of grapes. The machine enables the analysis of parameters such as physical condition (mildew, powdery mildew, botrytis), sunscald, berry size and colour, MOG and fill level.

The crates can be identified by means of a barcode or a QR code. The system can also interface with an automatic sorting machine and an information system for administrative and functional traceability.

The new Ampelos continuous flow pneumatic pressing system, from Della Toffola, is an integrated pressing system that allows work to be conducted in a continuous cycle. The system consists of three automatic presses linked by sensors and artificial intelligence integrated in a single structure.

The continuous mode is achieved by creating a synergy between several small individual presses used in modular expansions, with the priority on quality. This approach allows high capacities to be achieved with relatively small presses and offers a substantial quality edge, according to Della Toffola. The time between the start of filling and the end of must recovery from each press is very short, in contrast to large continuous presses.

Thanks to a series of interconnected sensors managed by algorithms and artificial intelligence, the pressing cycle is fully automatic in all its phases: from the beginning of filling to the end of washing, and the plant has all the advantages that are usually absent in a pressing cycle: speed, quality and yield. The system also adapts to the conditions, records the data of the good pressings, and uses them to improve the performance of the following pressings through a self-learning system.

Pellenc’s FILTR'ACTIV combination is a 2-in-1 equipment for the filtration of products with a high suspended solids content and wines. As the only technical alternative to rotary vacuum and press filters, the FILTR'ACTIV range combines the best of tangential tubular filtration and dynamic tangential flow filtration technology to achieve an excellent performance in terms of production flow rates, quality of the filtered product and yield.

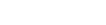

VitiBot now offers confined spraying with recovery panels for its fully electric and autonomous Bakus straddle tractor. This improves operator safety and profit margins due to the drastic reduction of drift and the recovery and reuse of sprayed products. It also uses very little electricity and is silent.

An Italian-made Tinaja with stainless-steel cover. Artenova’s new line of 400 and 180L Tinajas will be produced by hand using Impruneta clay. Prices start at €1,400 for the larger vessel and €750 for the 180L container.

Another new shape from Artenova is a large ‘Cognac’ wine-jar, suitable for processing grapes and ageing wine.

.png)