“We went to a stage where we were all worried about seed lignification and making sure every seed was brown before we picked. I think we went too far, to be honest, and I think sugars were getting out of hand and now I think there’s a really fine line between not picking too early and getting some phenolic ripeness without going overboard.”

There have been other changes, too, in his winemaking that have improved the quality of reds coming from some of Barossa’s finest old vineyards.

- Improved extraction through longer time on skins and warmer ferments.

- Increased use of native yeasts and whole bunches in the fermentation.

- Better quality French oak – but less of it – and much less American oak.

“We do our best from a winemaking perspective with what we’re given and then there’s environmental factors that play a part in the quality and evolution of the wine, so there’s lots of advances – a myriad of things we do throughout the year that will make a tenth of a percent difference but when you add them all up, it makes a massive difference.”

'Wine with more fruit, less oak and elegance are being rewarded'One of the reasons for the changes, he suggests, is domestic trends. “The Australian wine show circuit does set some agendas and styles – wine with more fruit, less oak and elegance are being rewarded and wine with overt oak, over-extraction or overripe notes are dismissed. The market, particularly Millennials and Gen-X, are looking for lighter styles hence the resurgence of modern Grenache out of the Barossa and McLaren Vale. I also think as winemakers we are more comfortable in our own skins and in making wine that suits our region’s varieties and not relying on outside influences, such as Robert Parker. I believe this is a confidence thing and a sign of winemaking maturity within the region.”

The improvements started in the vineyards. Grant Burge, the largest vineyard holder in the southern Barossa with 130ha on the Barossa Valley Floor (200-250m above sea level) and at high altitude in the Eden Valley, has changed its viticulture practices – to get more balanced vineyards and healthier soils – since Accolade Wines acquired the historic winery, vineyards and brand in 2015.

“That’s where the biggest quality gains are at the moment, in the vineyard,” Craig says. “We’re seeing that quality improve year in, year out.”

Moving in the direction of organic, they have:

- Abandoned herbicides and pesticides in many vineyards;

- Installed sheep for weed control over winter;

- Adopted mechanical weeding under vines;

- And only use sulphur and copper when absolutely necessary.

The result of all these changes is more elegant and structured wines that have great length and splendid freshness. “But you’ve got to be careful not to change style too much. It’s about adding on, getting complexity and layers without changing your brand,” Craig warns.

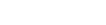

A good example of the modern style is Filsell which, according to Craig, “exemplifies what the Barossa Valley does so well”.

It has depth and power but also shows restraint.

Most of the Shiraz for this wine come from old vines. “We have the best access to old vines in the southern Barossa,” Craig points out. “It’s one of our strong points. We have vineyards that were planted in 1887, 1890, 1901, 1920, 1935 – there’s a whole array of old vineyards that give us something special.”

One of the big changes in the winemaking here is the inclusion of more whole clusters. With Filsell they have increased it to 25%.

“We’re finding that it adds another dimension, another structural element to the wine and sometimes it just takes the ripe fruit notes out of the wine,” he says.

The must is fermented in both closed stainless-steel and open concrete fermenters. The reason for the mixture, Craig says, is mainly practical: “We only have 14 concrete opens so, sometimes, it’s a question of space but also we like to keep some wine on skins for 30 days plus, and we can only do this in our closed-top stainless steel fermenters.”

The preferred fermentation temperature is 28°C. Craig says this is due to “trial and error. But we find this temperature allows good extraction and gives us control. If we go too much higher, we can lose the ferment and get much bigger daily sugar drops. If we go cooler, we tend not to get the extraction and ferments can drag. We do like to get time on skins with most of the sugar done, the solvent (alcohol) extraction is quite important.”

The open fermenters have wooden, wax-covered header boards to keep the cap submerged. “We find it gives us really good control because when it gets to threequarters of the way through ferment we’ve got enough extraction, we don’t need to pump over, move the pomace too much, so we get some really lovely characters. And the open fermenter, too, does get rid of a bit of alcohol.”

With the closed-top stainless steel fermenters they use about four pump-overs a day in the early stages and three to four rack and returns. Craig says this movement of the cap “is quite critical”.

The skins are pressed in a combination of basket and bag press. Craig is a big fan of their basket presses, which can take about 2 tonnes of wet skins. “We love them,” he says. “We can use gravity to fill the basket and the gentle extraction of pressing is brilliant, it would be very rare for us not to put all the pressings back into the free run from the basket press. No tearing of skins or seeds is the big bonus.”

They also use a 15-year-old Sutter bag press, which can take 5 tonnes of wet skins, because some of the larger stainless-steel fermenters don’t fit into the basket. “The bag press sits underneath the fermenters so we can use gravity to fill and we use an open screen press so extraction is relatively easy without rolling the press too often.”

When Craig started at Grant Burge back in 1993, they shared a contract winemaking facility with other producers. While the other producers were running wines into oak at 6 Baume, Grant Burge were doing it a 4-3 Baume. Now they leave it on skins until it’s nearly dry. Which could mean an extra two to five days – “because we feel that little extra extraction adds to the layers”.

He says they usually move it when it has only 3-5g/L of residual sugar to get better integration. “We don’t like putting clean wine into new oak, we find we don’t get any integration.”

The wine is then aged for 18 months in hogsheads and puncheons – a combination of French and American oak, 35% of which is new. The balance is matured in a combination of one-, two- and three-year-old French oak.

Switching from predominantly American to French oak is one of the biggest changes Craig has seen throughout the valley.

“We feel it gives us more subtlety, gives us the structure that we want,” adding: “The quality of the American oak we’re getting now is much, much better than we were getting a long time ago. When I first started, we were buying American oak and seasoning it in Australia! That’s plainly stupid because we don’t have the rainfall or conditions to season oak properly. The oak was a bit raw and horrible, but we’ve moved on a long way from then.”

The result is a wine with “more vibrant fruit and a tad less oak, and more structural,” he says during a Zoom tasting of the company’s latest range of vintage red wines, which include the 2018 Filsell Shiraz and the 2016 vintage of the company’s flagship wine, the standout Meshach Shiraz.

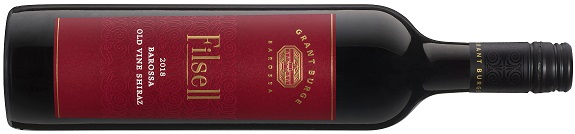

This wine is a tribute to the company’s founder. The Grant Burge estate dates back to 1865 when the Burge family first arrived from England and began making wine in Barossa – with the Grant Burge brand appearing in 1951. Meshach – named after Grant Burge’s great-grandfather – uses handpicked fruit from 16 or 17 parcels within three vineyards, including Filsell, which are over 100 years old.

Each of the parcels is treated slightly differently – some with a bit of whole bunch, some with longer time on skins, some with indigenous yeasts.

“We’ve been doing it long enough,” Craig says. “We know what works and what doesn’t. For example, the Filsell vineyard we know responds really well to about 25% whole bunch, but we know the Chaff Mill vineyard doesn’t like it at all, but we know the Chaff Mill vineyard responds really well to wild yeast. Those are the sorts of things you learn over a period of time, and trial and error. When we start to put these wines together it’s just getting those parcels that we can play with and put together the layers and the complexity that we particularly want in this wine.”

Meshach is only released in exceptional vintages. It’s the 24th release since the wine made its debut in 1988.

'This wine is all about layers and complexity'Craig says the 2016 is “comfortably in the top three Meshachs ever made”.

“This wine is all about layers and complexity and not in-your-face primary fruit. We want lots of stuff to happen in the glass.”

The selected fruit is fermented in stainless steel and concrete with 11% whole bunch to add to the spice in the aromatics of the wine and tannin structure. “Some years it works extremely well, just to add another dimension. I think it tends to present itself more as a cocoa-chocolate note in the wines,” Craig states.

The wine was then basket pressed before 20 months’ maturation in hogsheads, 37% new and split between 77% French and 23% American.

The winemaking team then select the best barrels to create the final blend.

Tasting the 2012 vintage alongside it, the movement towards better quality – but much less – French oak and much less American oak becomes obvious. Where the 2016 has 35% new oak, the 2012 had 65%. The 2012 also features fewer whole bunches in the ferment – just 8%.

As Craig says, the little changes add up and make a huge difference to the finished wine.

Grant Burge’s best wines in the International Wine Challenge.

.png)